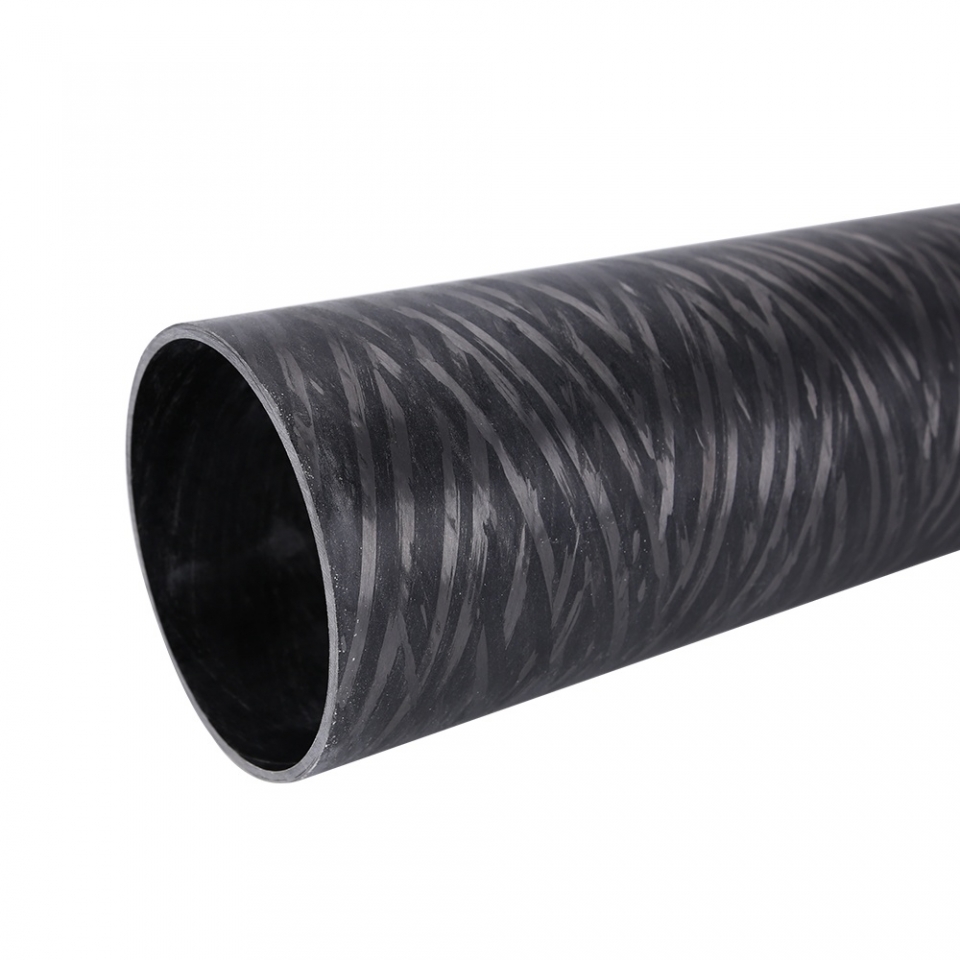

Carbon Fiber Insulation Casing OEM/ODM High Quality

1: Winding angle, 45°~65° (winding angle can be adjusted according to different requirements to achieve better mechanical properties);

3: Density, 2.00g/cm³;

4: Water absorption, less than 0.03%;

6: Glass transition temperature, 110~120℃;

7: Chemical resistance Mineral oil: excellent;

8: Solvent and dilute acid: excellent;

10: Tensile strength: 280 MPa in the axial direction; 600 MPa in the circumferential direction;

11: Shear strength: 150 MPa;

12: Bending strength: axial 350 MPa;

13: Compressive strength: axial 240 MPa;

14: Relative dielectric constant 2-3.2;

15: Dielectric loss factor 0.003-0.015;

16: Partial discharge ≤5;

17: Dielectric strength: axial 3~6kv/mm; radial 10~12kv/mm;

19: Power frequency shock: 50KV;

20: Heat resistance class: B, F, H;

21: inner diameter > 5mm; outer diameter < 300mm; length < 2000mm.

Contact available at :

Jacky Shen - Sales manager

Email:[email protected]

The Carbon Fiber Insulation Casing produced by our manufacturer Hetai is a composite material made of carbon fiber and epoxy resin, which offers numerous advantages including excellent thermal insulation properties, high strength, and lightweight. It has an operating temperature range of -40°C to 200°C, with a dielectric strength of 15kV/mm and a volume resistivity of 10^12 Ω·cm, providing reliable protection for sensitive components in harsh environments. The standard size ranges from 1mm to 500mm inner diameter and 0.5mm to 5mm wall thickness, with customized options available for different shapes and sizes. Carbon Fiber Insulation Casing is widely used in various industries such as aerospace, automotive, and marine, commonly serving as insulation sleeves for protecting sensitive components. We support customization for different shapes and sizes, and our professional team provides the best after-sales service.